Busch展示其新一代的挤出机度assing Systems

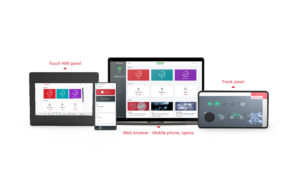

The new generation of Plastex vacuum systems for extruder degassing is ready for Industry 4.0 (Image source: Busch Vacuum Pumps and Systems)

The new Plastex vacuum systems can be programmed and monitored via a display. They are fully connected in order to exchange data with the extruder control system and can be operated directly via the extruder.

The fact that all components are connected means that Plastex vacuum systems are ready for Industry 4.0. The degassing system is controlled as required by a frequency-controlled drive motor. This means that the programmed vacuum level is precisely maintained – the energy saved in the process is a further benefit.

In recent years, Plastex vacuum systems have become widely established for degassing the melt in the screw zone of extruders. The model presented at K 2019 is equipped with a Mink claw vacuum pump. These vacuum pumps operate dryly, i.e. they do not require any operating fluids such as water, which can lead to high costs for treatment and disposal.

With the new generation of Plastex vacuum systems, Busch now impresses with further benefits. Thanks to the demand-dependent control and the option to adjust the vacuum level precisely to the material to be extruded, the extruder and the temperature conditions, it is possible to reproduce product quality without having to readjust the vacuum level manually via valves during the process. Plastex vacuum systems are available in different configurations and sizes. They are suitable for both compounds and master batches. They can be used to degas polyolefins such as PP/PE, EVA, PBT, ABS, EVOH or POM. Even the degassing of recycled material does not pose a problem for Busch s new Plastex vacuum systems. A flushing device allows to clean the vacuum pump after or during the process. It is also possible to program the cleaning intervals and the dosing of the cleaning agent.

The new Plastex vacuum systems control system also permanently monitors the condition of the filters and separators and immediately informs the operator via the display or extruder control system if, for example, a filter needs to be cleaned or condensate needs to be drained from the after-separator or the condensate collection container. The operator therefore always has an overview of all operating parameters. Any necessary action steps are immediately displayed to the operator. This increases reliability, simplifies operation and minimizes maintenance costs.

Busch貂爪真空泵不仅国lished themselves in the degassing of the melt during extrusion; this vacuum technology has also become the state of the art for pneumatic material feeding. Busch will present the latest development in Mink claw vacuum pumps at the trade show booth: the Mink MV 0600 B is equipped with a frequency-controlled drive motor as standard and can therefore adapt the pumping speed to the actual requirements. This means that not only can the material be transported as gently as possible, but further energy and cost savings are also possible.

Source:Dr.-Ing. K. Busch GmbH